Full body tiles are made through a process that compresses a mixture of clay, quartz, feldspar and silica under high temperature

The process makes the tile hard, with low porosity, which makes it highly water-resistant, a quality that does not cause internal damage and, therefore, maintains the strength of the tile. They are not as brittle as ceramic tiles and can withstand heat and pressure. Vitrified tiles do not react to alkali or acids and other chemicals and are stain-resistant.

Choosing the right kind of tile is very important especially in a high-traffic area. Industrial floors need to be really strong to bear huge static and dynamic loads as trucks with even 60 and more tonnage loads keep moving in industrial areas like warehouses and production areas.

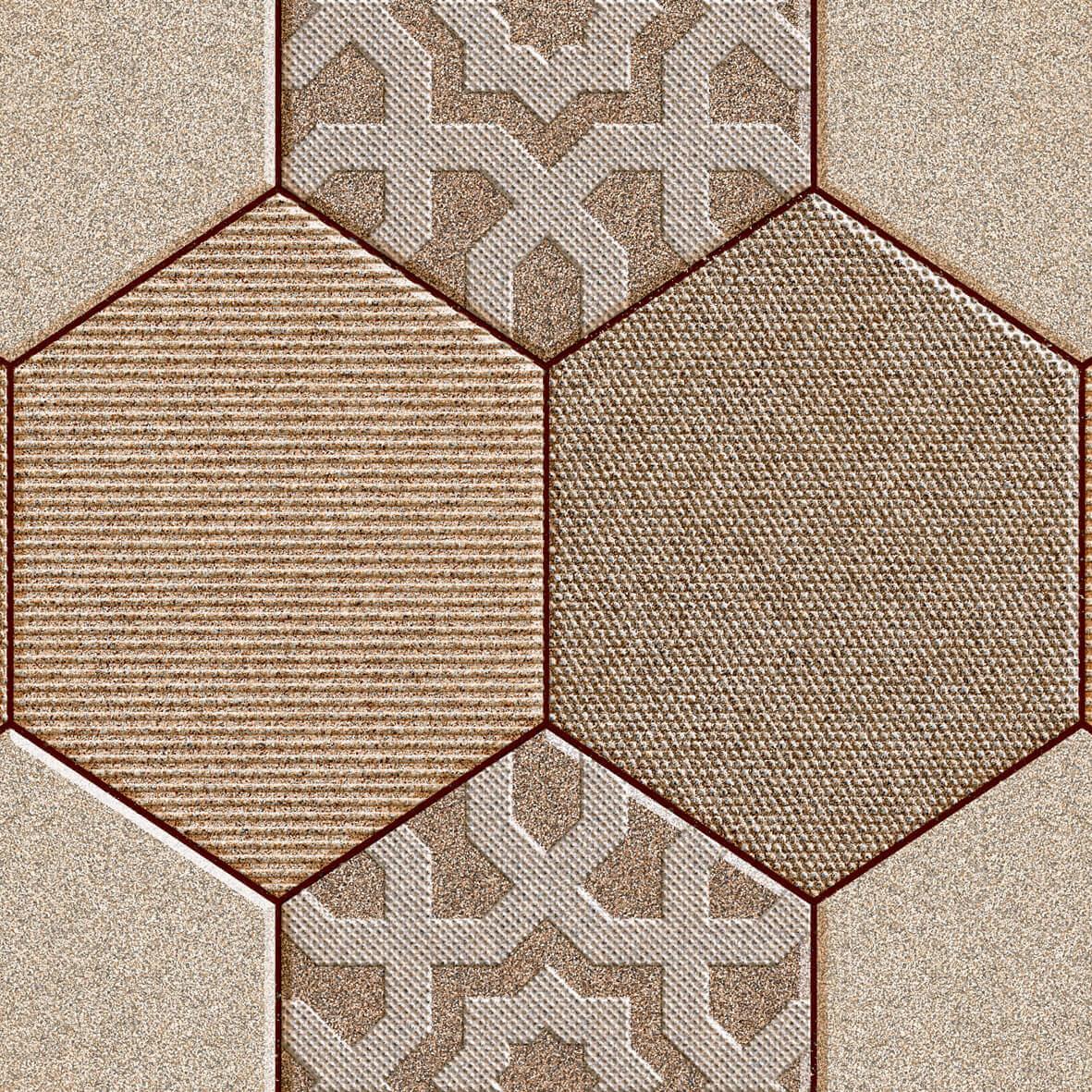

The colour and finish of these tiles are not affected by sunlight either, which makes them the best fit for your porch, garden area, bathrooms, and swimming pool deck area. These tiles are available in six shades and are a great choice to add more elegance to your already beautiful home.

They are easy to install and are a great choice for homes and offices. The installation process requires less time. Once installed, you won’t have to worry about replacing full body vitrified tiles for many years.

To check the durability and strength of these tiles, the company performed an experiment. We laid out three varieties of tiles and had a 60 tonnes cement truck pass over it. Actually, not just one but 100-plus trucks. The tiles came out unscathed and unaffected by the heavy load of these trucks. The three sets of tiles that we used included our collection of Sahara Gris full body tiles, Valencica (PCM, natural pine wood), and GVT (DGVT rosewood brown). At Orientbell, you can select the best flooring tiles from a huge variety.

Still don’t believe us? Here’s the proof